When it comes to heating, ventilation, and air conditioning systems, two of the most discussed yet often misunderstood concepts are CFM (cubic feet per minute) and static pressure, sometimes known as airflow volume (CFM) and airflow resistance (static pressure).

These terms may sound technical, but they are the foundation of how air moves through ducting and into your home. Knowing how these factors interact, will greatly help if you're in the market for a new HVAC system, need to fix issues with heating and cooling, or are just plain curious.

- Why the Balance Between Airflow and Static Pressure is Critical

- What Does CFM Mean?

- What Is Static Pressure?

- How Does Static Pressure Affect My System?

- What Is the Normal Static Pressure for an AC Unit?

- How Do I Calculate the Static Pressure of My System?

- Do I Need to Worry about CFM and Static Pressure?

Why the Balance Between Airflow and Static Pressure Is Critical

Imagine the HVAC system as a human circulatory system, with the fan and blower acting like a heart and the ducts acting like blood vessels.

If the blood vessels are too small, constricted, or clogged, the “heart” has to work much harder. That's the essence of static pressure.

Similarly, various body parts suffer if the heart isn't pumping enough blood. In HVAC terms, insufficient airflow (low CFM) can result in hot or cold spots, poor indoor air quality, and higher energy usage.

What Does CFM Measure?

CFM, or cubic feet per minute, measures the amount of air moving through your system each minute. If you imagine the air flowing through your ducts as water streaming through a hose, CFM measures the volume of air “flow-through” in one minute of operation.

In ventilation systems, like an Energy Recovery Ventilator/Heat Recovery Ventilator or Air Supply Fan, the CFM rating directly impacts how effectively air is delivered to different spaces. When you set your thermostat, you depend on a specific volume of air moving through the ducts and into each room. A higher CFM typically means more air is circulated and is especially helpful in larger spaces or spaces with complicated duct designs.

Factors Affecting CFM

- Fan Size and Speed: A larger or more powerful fan can move more air.

- Duct Size and Layout: Narrow or twisting ducts can limit how much air reaches each room.

- Filter Cleanliness and Restriction: A clogged filter restricts airflow, reducing CFM.

What Does Static Pressure Measure?

While CFM represents how much air is moving, static pressure measures how hard the fan has to work to move that air. Technically, it's the resistance to airflow within your duct system, measured in inches of water column (inches w.g.). If you've ever tried blowing through a thin straw, you need more force to move the same air as blowing through a wider straw. That extra “push” is essentially static pressure at work.

Where Static Pressure Occurs in a System

Any element that forces air to deviate from a straight path or pass through a restrictive medium contributes to static pressure. This includes:

- Ducts (length, diameter, and layout can all add resistance).

- Filters (especially if dirty or high-efficiency types like HEPA).

- Evaporator coils in AC systems or heating coils in furnaces.

- Bends, dampers, registers, and other accessories.

Each component might add just a bit of resistance, but all together, it can cause significant pressure that the fan must overcome.

Factors Influencing Static Pressure

- Duct design: Longer duct runs and sharp bends mean more resistance.

- Duct condition: Leaks, blockages, and poor connections can raise or lower overall pressure unpredictably.

- Filters and accessories: More specialized filtration (e.g., HEPA filters) or closed dampers can increase static pressure.

Why Static Pressure Matters

Static pressure determines how efficiently air can be pushed through a system. If it's too high, the fan may struggle to deliver adequate airflow (CFM), leading to discomfort and higher energy costs. If it's too low, it might indicate your ducts are oversized or leaking, which can also compromise system performance.

How Does Static Pressure Affect My System?

Impact on Fan Performance

Airflow (CFM) decreases when static pressure increases in most HVAC or ventilation systems. Each system is designed to supply a particular air volume against a specific resistance.

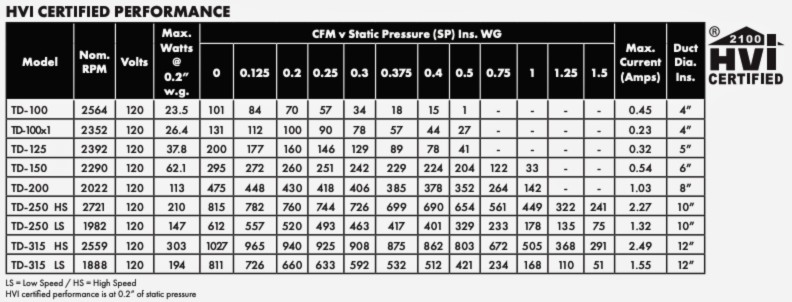

The relationship between airflow and static pressure can be seen on fan curves, which manufacturers often provide. The higher the pressure in your system, the harder your fan or blower must work to maintain the same airflow, potentially leading to reduced CFM if the fan can't keep up.

System Efficiency

Increased resistance means increased energy consumption. To illustrate, consider an example from the field: moving 10,000 CFM at 0.5 inches w.g. might require 1.6 horsepower (roughly 4.09 amps), but doubling that resistance to 1 inch w.g. can raise the power requirement to 2.5 horsepower (about 6.39 amps).

This represents a 55 percent increase in power usage, directly impacting your electric bills. The more your system struggles against high static pressure, the more you'll notice in monthly operational costs.

Equipment Wear and Tear

Over time, a fan that has to fight excessively high static pressure may overheat or fail prematurely. Other components, such as the compressor in an air conditioner, can also experience added stress due to improper airflow. Filters may need replacing more frequently, and motors might require earlier replacement. In short, high static pressure can slowly degrade multiple parts of your HVAC system.

Indoor Comfort and Air Quality

An HVAC system battling high static pressure often underperforms in distributing conditioned air evenly throughout the building. That can mean hot or cold spots, insufficient humidity control, and an overall decrease in indoor air quality. Filters may not work as efficiently if air struggles to pass through them, potentially causing an accumulation of harmful airborne particulates in your living spaces.

By contrast, if static pressure is too low, you might suspect duct leaks or improperly sized ducts. This reduces filtration effectiveness and possibly pulls in unconditioned or contaminated air from attics or crawl spaces. Either scenario—a system fighting against too much or too little resistance—detracts from optimal comfort, efficiency, and air quality.

What Is the Normal Static Pressure for an AC Unit?

Typical Ranges

For many residential systems, 0.5 inches w.g. is the commonly referenced target for total external static pressure. This is often considered the sweet spot for balancing efficient airflow with quiet operation and effective filtration.

Some modern high-efficiency systems may be rated to handle slightly higher static pressures, up to 0.7 to 0.8 inches w.g., without major performance issues. However, once you start nearing 0.9 inches w.g., airflow can drop significantly, and energy usage tends to spike.

Variation by Manufacturer and System Design

It's essential to note that each manufacturer has specific guidelines regarding acceptable static pressures for their equipment. A premium system with advanced variable-speed blowers might tolerate higher pressures than a basic single-speed fan. The best approach is to check your HVAC system's documentation and consult with professionals to ensure you're within the recommended range.

How Do I Calculate the Static Pressure of My System?

It may be tempting to figure out static pressure by yourself. However, attempting to calculate your static pressure from scratch is not recommended. Formulating an accurate measurement typically requires specialized tools like pressure gauges designed for HVAC use and a certain level of expertise. Furthermore, you may have to drill small test holes in your ducts in specific locations to measure the pressure drop across various components.

If you have a strong background in HVAC or are very comfortable with mechanical tasks, you might estimate static pressure using readings at supply and return ducts. But keep in mind that without a professional's guidance, it's easy to misinterpret the readings or fail to gather them in a way that accurately reflects the performance of the entire system.

For most people, leaving this job to an HVAC professional is wise. A trained technician can perform the necessary tests, interpret the results, and recommend steps to address any issues. For example, they might suggest altering ductwork, upgrading filters, or adjusting fan speeds if static pressure is out of range.

Do I Really Need to Worry about CFM and Static Pressure?

Understanding CFM and static pressure may seem daunting, but these factors are at the heart of your HVAC system's performance. Knowing the basics can help you spot potential problems—like noisy vents, uneven temperatures, or higher energy bills—before they escalate into costly repairs or system failures. If in doubt, consult an HVAC professional. They have the experience, tools, and data to accurately measure and adjust your system's static pressure.

Still need help understanding CFM and Static Pressure or another topic entirely? Check out Sylvane's Knowledge Center for a complete library of topics about air quality and home comfort, or call our product experts at 1-800-934-9194.